Compound Steel Grating Drain Grill Grating For Floor Grating , Drain , Trench And Ship

Compund steel grating

Compound steel grating is a product composed of steel grating with certain crossing capacity and checkered plate with sealing surface.

Compound steel grating can be composed of any type of steel grating and checkered plate with different thickness.

The compound steel grating is commonly used as the base plate of series 3 (flat steel spacing 60mm), or series 1 (flat steel spacing 30mm) or series 2 (flat steel spacing 40mm) steel grating; The checkered steel grating is usually 3mm thick, and 4mm, 5mm and 6mm plates can also be used.

The material of compund steel grating

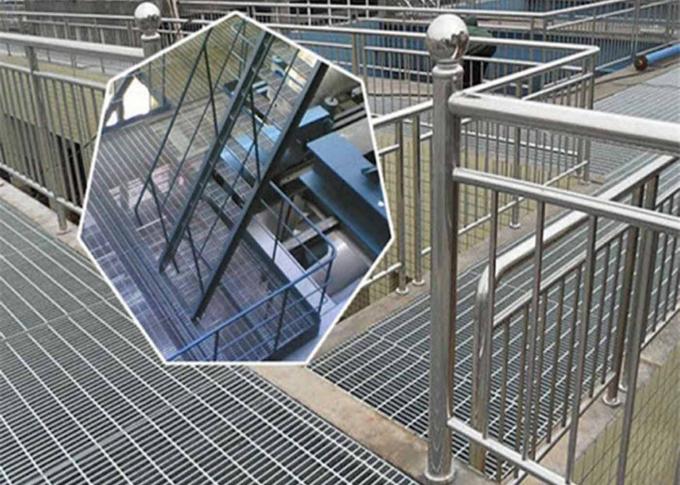

Thecompound steel grating is generally made of carbon steel, and the surface is hot-dip galvanized, which can prevent oxidation. It can also be made of stainless steel. The steel grating has the properties of ventilation, lighting, heat dissipation, anti-skid and explosion-proof.

Another is stainless steel grating, which is much more expensive than conventional galvanized steel grating. It is generally used in food factories, kitchen drainage, pharmaceutical factories and other areas with high anti-corrosion requirements

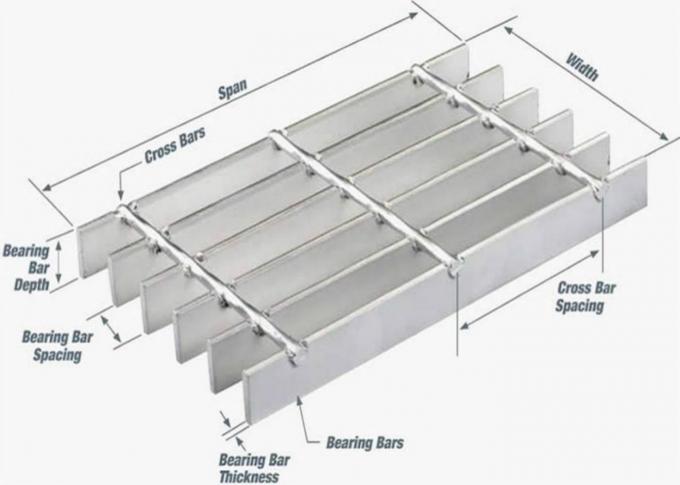

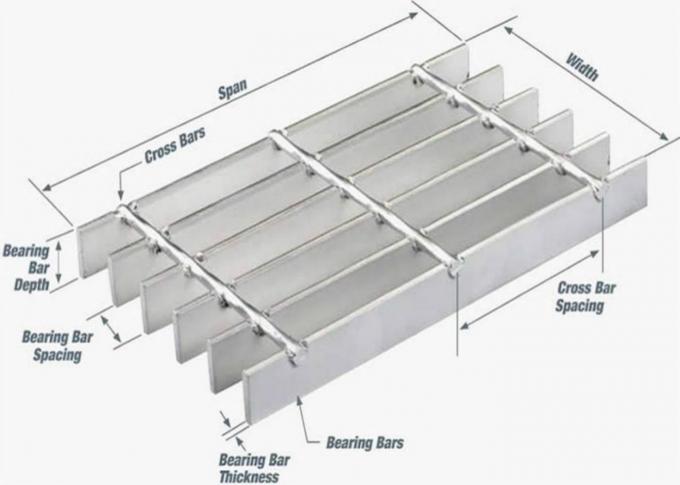

Structure of the metal grating

Material saving: The metal grating is the most economical way to bear the same load. Accordingly, the material of supporting structure can be reduced.

Reduce investment: save materials, labor, construction period and cleaning and maintenance.

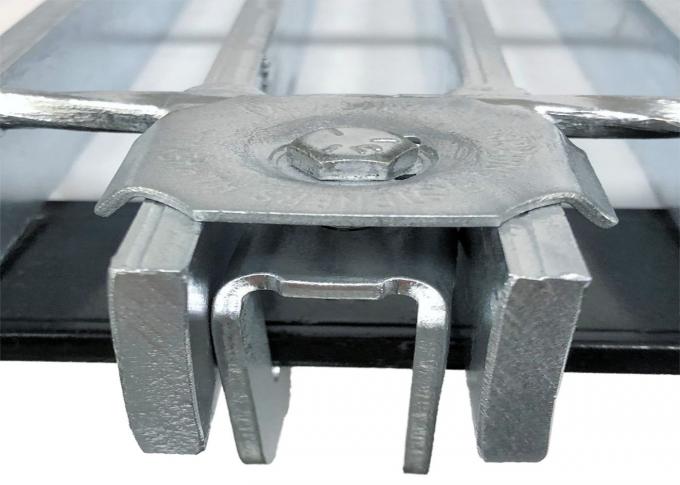

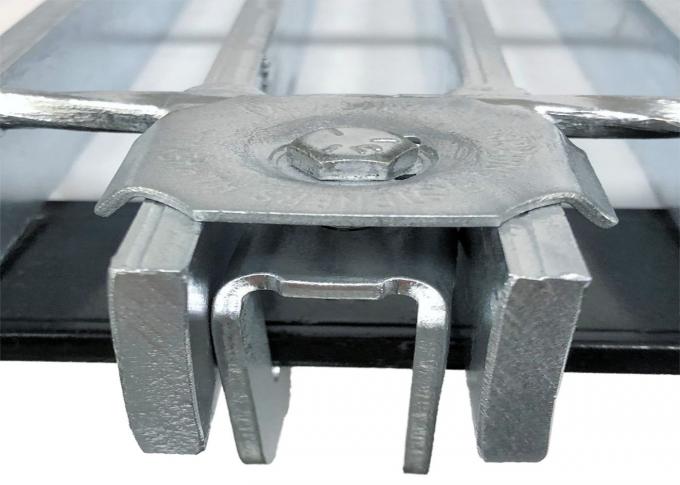

Simple construction: fix the pre installed support with bolt clamp or welding, and one person can complete it.

Save time: The metal grating does not need to be reprocessed on site, and the installation is very fast.

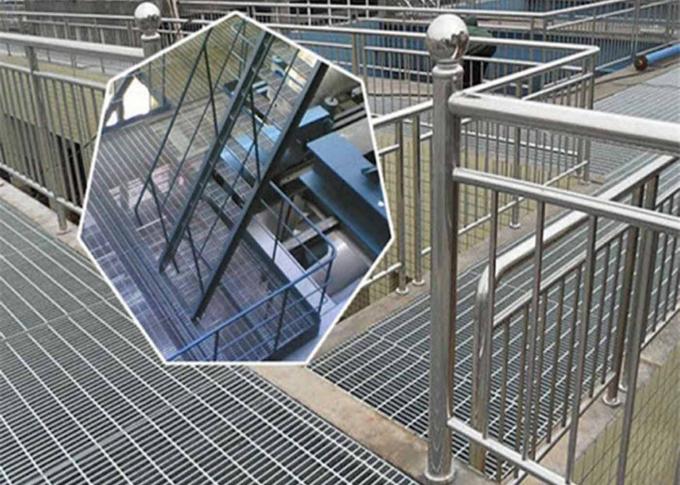

Application of the metal grating

Due to its wide range of applications, including ships, power plants, industrial plants and street drain covers, the grating has become a necessary product for the maintenance of life heavy infrastructure.

Hot dipped galvanized steel bar grating type

Welded Grating

Economical design ideal for most industrial applications. Manufactured by welding the bearing and cross bar intersection, typically with automated forge welding equipment. Available in carbon and stainless steel.

Swage Locked Grating

Popular for the manufacture of aluminum, stainless steel, and close mesh gratings. Cross bars are inserted into pre-punched holes in the bearing bars and hydraulically deformed to lock the bars in place.

Dovetail Pressure Locked Grating

Assembled by inserting pre-punched bearing and cross bars into an “eggcrate” configuration and deforming the cross bars under intense hydraulic pressure. Available in all materials and ideal for architectural and ornamental applications.

Riveted Grating

Exceptionally durable grating manufactured by riveting bearing bars and bent connecting bars at their contact points. Excellent for applications involving impact loads and repetitive traffic patterns.

Hot dipped galvanized steel bar grating drawing

Hot dipped galvanized steel bar grating fastener

hot dipped galvanized steel bar grating welding machine

Package of the galvanized compound steel grating

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!