Mine sieve screen Johnson wedge wire screen Dust water treatment 304 316 316L stainless steel

Mine sieve screen screen

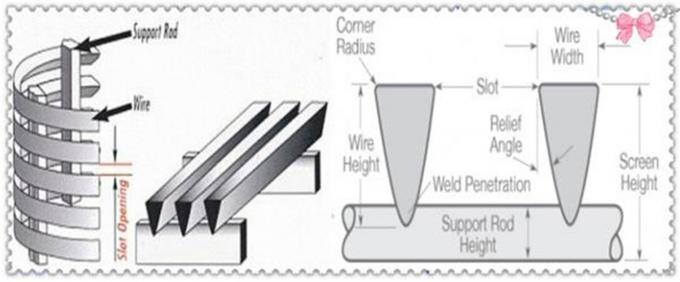

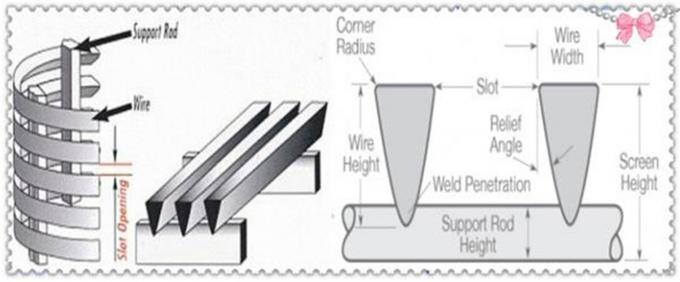

Mine sieve screen, , also known as slot screen and Johnson screen, is an industrial screen developed by Johnson company. It is composed of special-shaped metal wires and support rods of different shapes. It is continuously welded by a specially designed resistance welding machine.

Material of Mine sieve screen.

Stainless steel 201202205304316316l, 321 and other stainless steel wedge wires, trapezoidal wires, etc.

Advantage of the Mine sieve screen

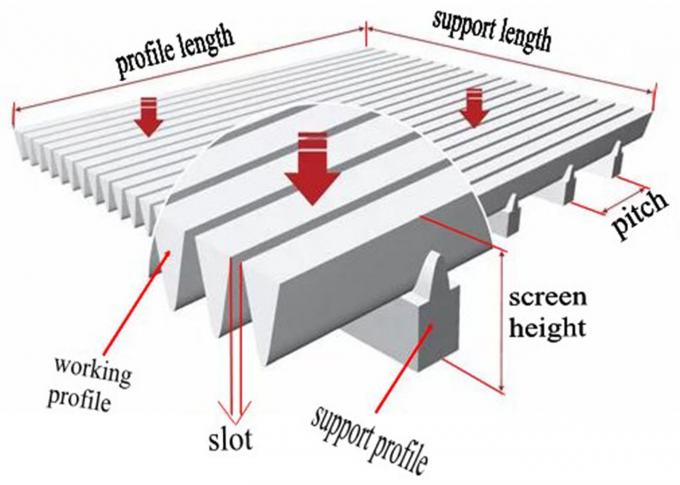

The Johnson wedge wire screen is easy to leak. The mine sieve screen bar is made of cold rolled stainless steel wire. The support bar is welded by automatic mine screen machine equipment.

The Johnson wedge wire screen seam is uniform, the welding quality is stable, the opening rate is high, the service life is long, and the strength and bearing capacity are very high.

The mine sieve screen bar is trapezoidal, narrow at the top and wide at the bottom, so that the slit screen has a high screening rate, improves production capacity and saves costs.

Application of the Mine sieve screen

The mine sieve screen is used in mining, coal, petroleum, chemical fertilizer, grain, salt, environmental protection and other industries. Screening liquid, powder and other materials. Petroleum, chemical, metallurgy, mining, pharmaceutical purification, drilling fluid purification, etc.

Can be customized according to customer needs.

The Specification of Mine sieve screen

Stainless steel linear vibrating screen bar: 0.75mm-5mm

Stainless steel linear vibrating screen gap: 0.05mm-80mm mesh: 1-400 mesh

| Specification (wedge wire): |

Width(mm): 1.50 1.80 2.30 3.00 3.30 3.70 4.00 |

| Height(mm): 2.20 2.50 2.70 3.60 4.30 4.70 5.60 6.30 7.00 |

| Specification (support rod): |

Width(mm): 2.30 3.00 3.30 3.70 |

| Height(mm): 2.70 3.60 4.70 5.60 6.30 |

| Round: From 2.50mm to 6.0mm |

| Note: other specifications available as per request |

| Slot size |

0.10, 0.15, 0.20, 0.25, 0.30…… 6.00mm also achieved upon request. |

| Material: |

stainless steel (304/304L/316/316L etc.) or galvanized low carton (LCG) |

| Length |

up to 6 meters. |

| Diameter |

139.7mm or from 25mm to 1200mm. |

| End connection |

threaded couplings |

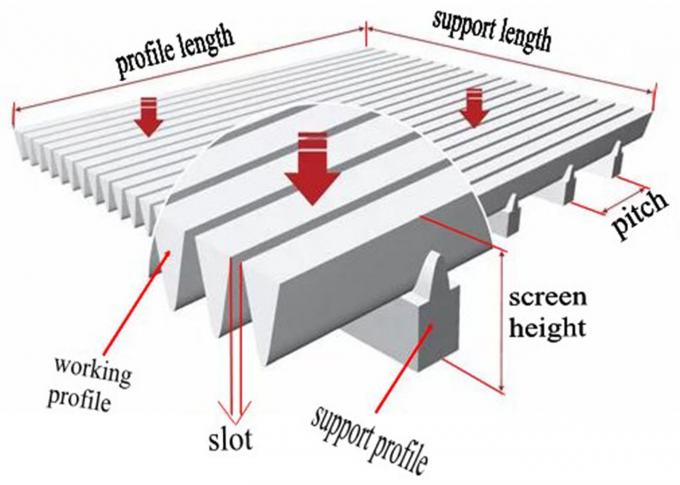

The structure of the stainless steel johnson wedge wire screen

In the past, the metal wire meshscreen woven by metal wires was widely used in industry. Due to the large contact area between solid particles (catalyst, molecular sieve and various filter materials) and the mesh, the particles are easy to block and get stuck in the square holes of the metal wire mesh screen, resulting in increased pressure drop, which makes the device unable to operate and difficult to maintain. However, the Johnson screen and solid particles are only in contact at two points, so it is not easy to block and get stuck

The drawing of the Stainless steel Johnson screen

Advantage of the Mine sieve screen wedge Johson wire screen

Johnson screen has a large opening range and a high opening rate.

The Johnson screen shaped wire is welded to each intersection of the support rod, so the accuracy is high,

Johnson screen is welded by fully automatic machinery with accurate gap.

There are only two points of contact between the continuous gap of Johnson screen and solid particles, which is not easy to block.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!